California Vibratory Feeders, Inc.

World class builders of automation machinery since 1972.

Automation is our passion and quality is our commitment!

Products

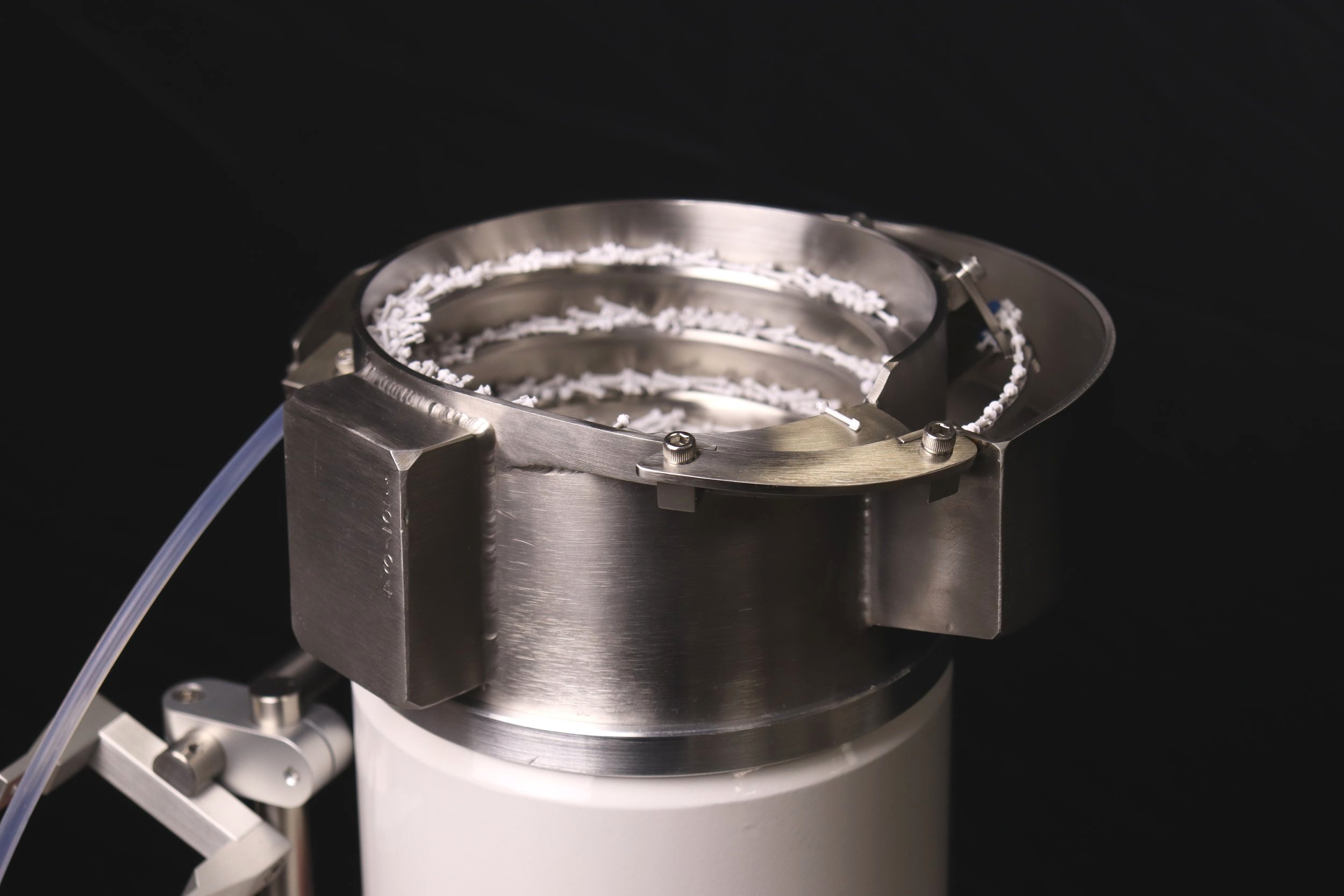

VIBRATORY FEEDER BOWL

HOPPERS AND PREFEEEDERS

INLINE FEEDERS

SOUND ENCLOSURES

Services

-

Elevate your automation processes with a custom feeder bowl meticulously tailored to your unique part specifications. At CalVibes, we specialize in crafting precision solutions designed to optimize efficiency and accuracy in your operations. No matter the complexity or size of your components, our team is dedicated to engineering a feeder bowl that seamlessly integrates into your business. Request a quote now, and let us transform your vision into a reality, delivering a tailored feeding solution that aligns perfectly with your specific needs.

-

Streamline your operational needs with our ready-to-ship parts from our standard product line at California Vibratory Feeders. Our comprehensive range of standardized solutions is designed for quick deployment, ensuring swift and efficient integration into your processes. Experience the convenience of high-quality, readily available components that meet industry standards. Request a quote now, and let us provide you with the reliable and cost-effective parts you need to enhance your workflow without delay.

-

Experience unparalleled support for your equipment with our expert service technicians at Cal Vibes. Our skilled professionals are ready to address any maintenance or troubleshooting needs, ensuring the seamless operation of your machinery. Request a quote now, and let us provide you with the responsive and reliable service technicians who can keep your systems running smoothly. Count on us for swift and effective technical support to maximize the performance and longevity of your equipment.

Industries served

Medical, Cosmetic, Pharmaceutical, Automotive, Aerospace, Electronics, Irrigation, Government, Hardware, Defense, Industrial and many more!

Proudly crafting precision solutions right here in America

-

CONSULTATION

We understand the path you need to take to get the feeder product you need. Every unique part and customer have different expectations, allow us to help assist you in meeting your needs

-

DESIGN

We utilize highly intuitive C.A.D. technology including Solid Works. From concept to completion we maintain the highest level of quality and customer service.

-

DEVELOPMENT

Over the past 50 years, we've been at the forefront of vibratory feeder development, constantly pushing the boundaries of technology. Our dedication to innovation has resulted in feeders that set new industry standards, delivering unparalleled precision and reliability. Each step in our development journey has been fueled by a passion for optimizing manufacturing and processing operations.